Mail : sales@hariomsteel.com

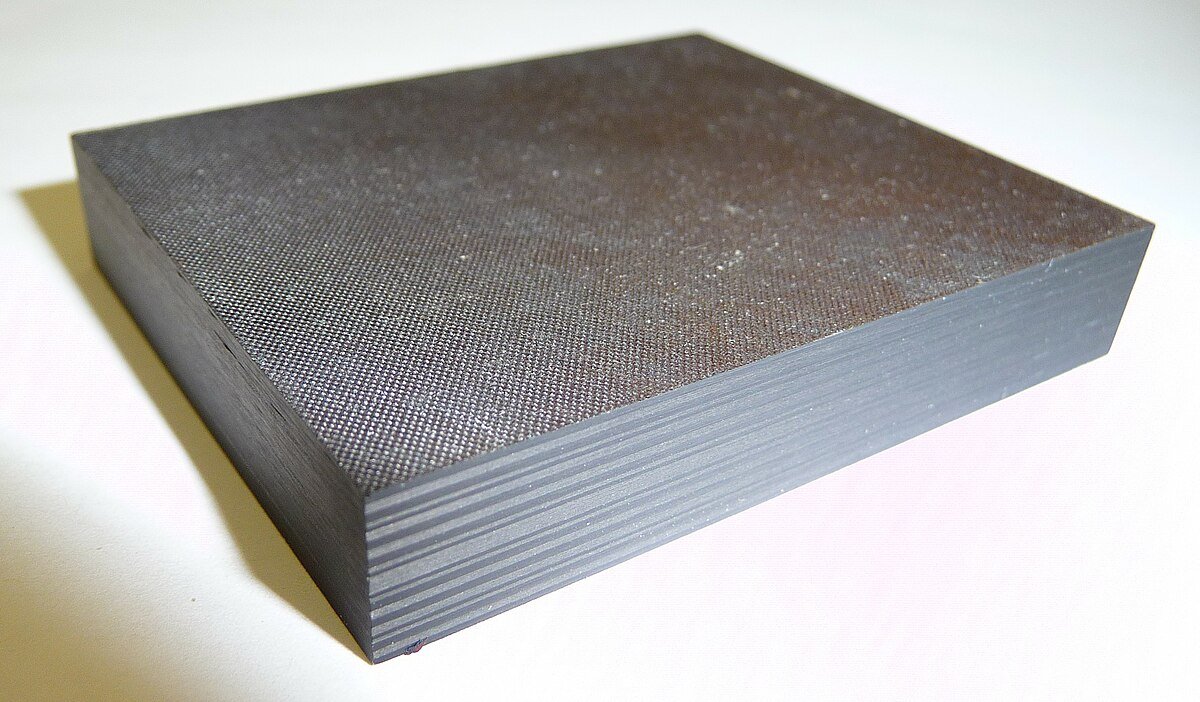

Composite Plates

Introduction

Composite plates are engineered materials that combine multiple components to achieve superior properties. These plates typically consist of a core material sandwiched between two outer layers of different materials, resulting in enhanced strength-to-weight ratios, improved durability, and additional functionalities. Commonly used in aerospace, automotive, and construction industries, composite plates offer a versatile solution for demanding applications.

The composite construction allows for tailored properties such as lightweight construction, high impact resistance, and resistance to environmental factors.

- High strength-to-weight ratio

- Enhanced impact resistance

- Excellent durability

- Customizable properties

- Resistance to environmental factors

Features of Composite Plates

- Lightweight: Composite plates are significantly lighter than traditional materials, making them ideal for applications where weight is a critical factor.

- High Strength: These plates offer high strength and rigidity while maintaining a low weight, suitable for structural applications.

- Impact Resistance: Composite materials are designed to absorb and dissipate impact energy, providing excellent protection against damage.

- Corrosion Resistance: Many composites are resistant to corrosion, making them suitable for use in harsh environments.

- Customizability: The properties of composite plates can be tailored to meet specific performance requirements through the choice of core and outer materials.

Composite Plate Characteristics

- Core Materials: Common core materials include honeycomb structures, foam cores, and balsa wood, each offering different performance benefits.

- Outer Layers: Typically made from high-strength materials such as fiberglass, carbon fiber, or aramid fibers to provide structural integrity.

- Manufacturing Techniques: Composite plates can be manufactured using techniques such as lay-up, vacuum bagging, and autoclave processing to achieve desired properties.

- Thermal Properties: Composites can be designed to withstand high temperatures and provide thermal insulation.

- Acoustic Properties: Some composites are designed to offer sound dampening and acoustic insulation benefits.

Composite Plate Specifications

- Core Types: Honeycomb, foam, balsa wood, and custom core materials

- Outer Layer Materials: Fiberglass, carbon fiber, aramid fiber, and other high-strength composites

- Thickness Range: Customizable based on application requirements

- Size Range: Available in various sizes, typically up to 96" x 120" with custom sizes upon request

- Standards and Specifications: ASTM D638, ASTM D790, ISO 527, ISO 14125

- Finish Options: Available in various finishes including smooth, textured, and custom coatings