Mail : sales@hariomsteel.com

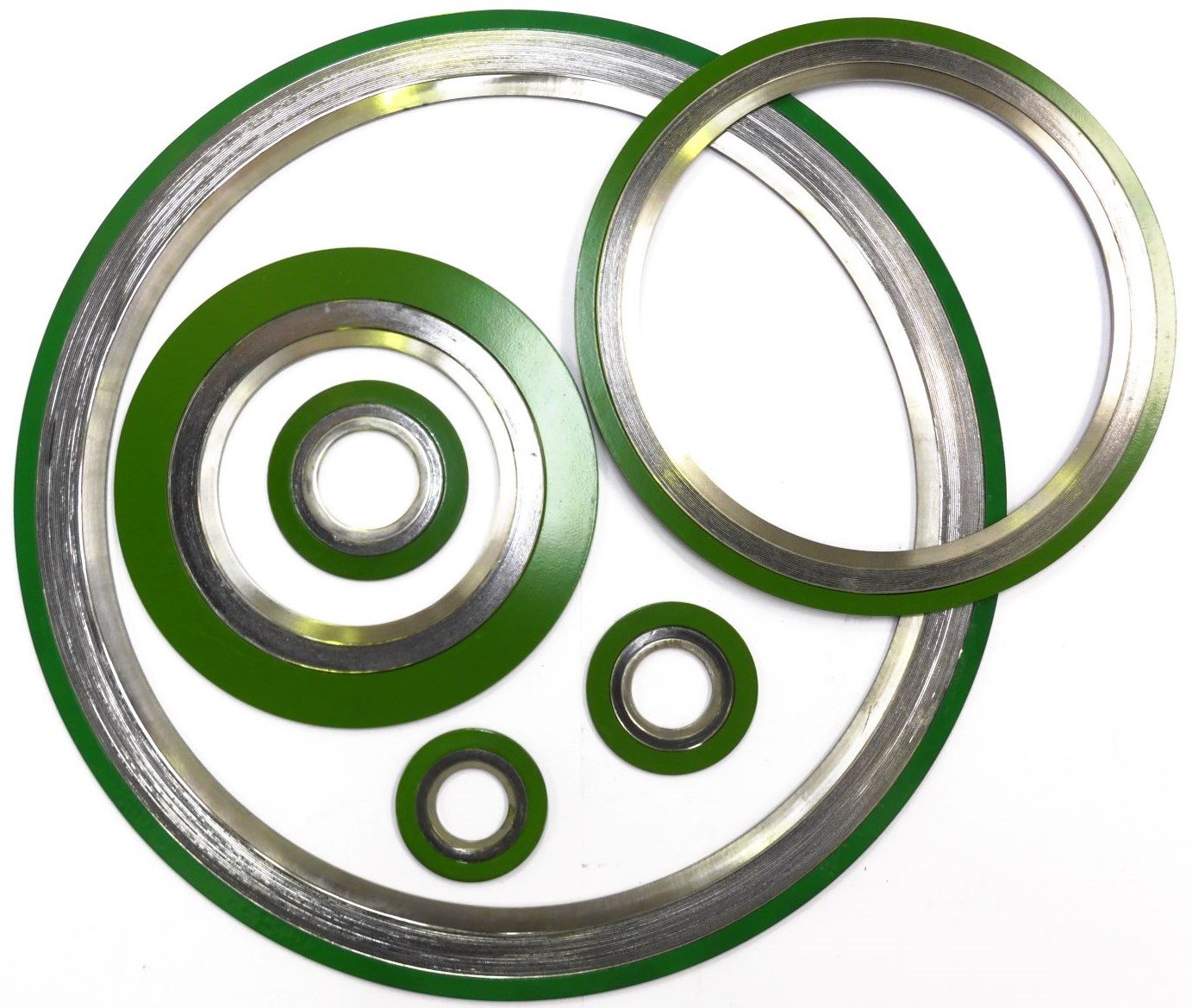

Spiral Wound Gasket

Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties. Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

These gaskets are manufactured to International specifications such as BS, API, ASME, DIN. We also manufacture to customer's specifications

Material Grades :

| Material Type | Grades |

|---|---|

| Carbon Steel | Carbon |

| Stainless Steel | 304, 304L, 316, 316L, 316Ti, 321, 347, 347H, 410, 430, |

| Nickel | 200 |

| Inconel | 600, 625, 800 |

| Incoloy | 800, 825 |

| Titanium | Grade 2, Grade 7 |

| Hastelloy | C-22, C-2000 |

| Copper | Copper |

Spiral Wound Gaskets Specifications:

| Specification | Details |

|---|---|

| Material | Carbon Steel, Stainless Steel, Nickel, Inconel, Incoloy, Titanium, Hastelloy, Copper |

| Filler Material | Graphite, PTFE, Non-asbestos |

| Type | Spiral Wound |

| Temperature Range | -200°C to 600°C (-328°F to 1112°F) |

| Pressure Rating | Up to 3000 psi (varies with material and design) |

| Standards | ASME, API, DIN |

| Sizes | Customizable |

| Applications | Chemical, Petrochemical, Oil & Gas, Power Generation |

| Production Technique | Spiral Winding, Heat Treated and Machined |

Dimension Chart :

| Nominal Bore (mm) | Inner Ring ID #150 | Inner Ring ID #300 | Inner Ring ID #600 | Sealing Element ID #150 | Sealing Element ID #300 | Sealing Element ID #600 | Sealing Element OD #150 | Sealing Element OD #300 | Sealing Element OD #600 | Centering Ring OD #150 | Centering Ring OD #300 | Centering Ring OD #600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 14.2 | 14.2 | - | 19.1 | 19.1 | - | 31.8 | 31.8 | - | 47.8 | 54.1 | - |

| 20 | 20.6 | 20.6 | 20.6 | 25.4 | 25.4 | 25.4 | 39.6 | 39.6 | 39.6 | 57.2 | 66.8 | - |

| 25 | 26.9 | 26.9 | 26.9 | 31.8 | - | 31.8 | 47.8 | 47.8 | 47.8 | 68.8 | 73.2 | - |

| 32 | 38.1 | 38.1 | 38.1 | 47.8 | 47.8 | 47.8 | 60.5 | 60.5 | 60.5 | 76.2 | 82.6 | - |

| 40 | 44.5 | 44.5 | - | 54.1 | 54.1 | - | 69.9 | 69.9 | 69.9 | 85.9 | 95.3 | - |

| 50 | 55.6 | 55.6 | 55.6 | 69.9 | 69.9 | 69.9 | 85.9 | 85.9 | 85.9 | 104.9 | 95.3 | - |

| 65 | 66.5 | 66.5 | - | 82.6 | 82.6 | - | 98.6 | 98.6 | - | 124.0 | 130.3 | - |

| 80 | 81.0 | 81.0 | 78.7 | 101.6 | 101.6 | 101.6 | 120.7 | 120.7 | 120.7 | 136.7 | 149.4 | - |

| 100 | 106.4 | 102.6 | 102.6 | 127.0 | 127.0 | 127.0 | 149.4 | 149.4 | 149.4 | 174.8 | 181.1 | - |

Application of Spiral Wound Gasket:

Spiral wound gaskets are commonly used in a variety of industries due to their ability to withstand high pressure and temperature variations. They are primarily used in:

- Petrochemical industry for sealing flanges and valves.

- Oil and gas pipelines to prevent leaks.

- Power generation plants for heat exchangers and steam lines.

- Chemical processing facilities for reactors and other high-pressure systems.

- Marine applications for engine and boiler seals.