Mail : sales@hariomsteel.com

Lock Nuts

Lock nuts are specially designed to prevent loosening under vibration and torque. They come in various types, including nylon insert lock nuts, metal lock nuts, and prevailing torque nuts.

- Prevents loosening due to vibration

- Ideal for applications with high vibration

- Available in nylon insert and metal variants

- Ensures secure and long-lasting fastening

- Used in automotive, machinery, and aerospace industries

Lock Nuts Specification Table

| Specification | Description |

|---|---|

| Lock Nuts Standard | EU, IFI, CSN, Italian, ASME, British BS, Indian IS, ISO, DIN, Polish PN, SAE |

| Lock Nuts Sizes | 3 mm to 200 mm |

| Lock Nuts Length | 1/2″ to 2″ |

| Lock Nuts Materials | High Tensile, Carbon Steel, Stainless Steel, Inconel Fasteners, Incoloy Fasteners, Hastelloy Fasteners, Monel Fasteners, Silicon Bronze, Phosphor Bronze, Aluminium Bronze, Nickel, Brass, Copper, Copper Nickel, Nitronic, Nimonic, ASME, ASTM |

| Lock Nuts Coating | PTFE Coated Lock Nuts, Hot Dip Galvanized Lock Nuts, Yellow Zinc Plated Lock Nuts, Blue Zinc Plated Lock Nuts, Black Zinc Plated Lock Nuts, Zinc Cobalt Plated Lock Nuts, Aluminium Zinc Flake Coated Lock Nuts, Black Phosphate Lock Nuts, Zinc Plated Lock Nuts, Nickel Plated Lock Nuts |

| High Tensile Grades | 8.8 Lock Nuts, 10.9 Lock Nuts, 12.9 Lock Nuts, 14.9 Lock Nuts |

| Lock Nuts Forming | Hot Forged Lock Nuts & Cold Forged Lock Nuts |

Lock Nuts Materials / Grades

| Materials | Grades |

|---|---|

| Stainless Steel | ASTM / ASME SA 312 GR. TP 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L . |

| High Tensile | 8.8, 10.9, 12.9, 14.9 |

| Duplex Steel | UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

| Carbon Steel | ASTM / ASME A 335 GRP 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91 |

| Alloys Steel | ASTM / ASME A/SA 193 / 194 – B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

| Nickel Alloys | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

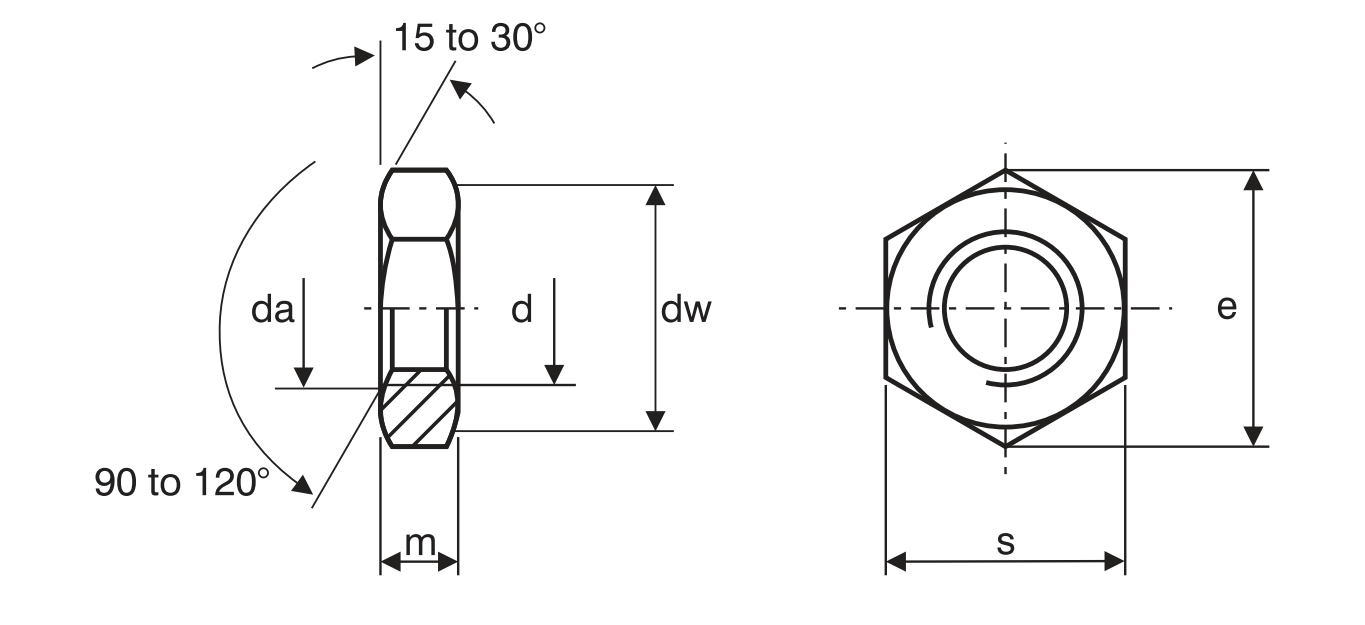

Lock Nuts Dimensions Chart:

| Nominal size and thread diameter d | p (coarse pitch series) | da min. | da max. | dw min. | e min. | m min. | m max. | s min. | s nom. |

|---|---|---|---|---|---|---|---|---|---|

| M10 | 1.50 | 10.00 | 10.80 | 15.60 | 18.90 | 4.70 | 5.00 | 16.73 | 17.00 |

| M12 | 1.75 | 12.00 | 13.00 | 17.40 | 21.10 | 5.70 | 6.00 | 18.67 | 19.00 |

| M14 | 2.00 | 14.00 | 15.10 | 20.50 | 24.49 | 6.42 | 7.00 | 20.67 | 21.00 |

| M16 | 2.00 | 16.00 | 17.30 | 22.50 | 26.75 | 7.42 | 8.00 | 23.67 | 24.00 |

| M18 | 2.50 | 18.00 | 19.50 | 24.90 | 29.56 | 8.42 | 9.00 | 26.16 | 27.00 |

| M20 | 2.50 | 20.00 | 21.60 | 27.70 | 32.95 | 9.10 | 10.00 | 29.16 | 30.00 |

| M22 | 2.50 | 22.00 | 23.80 | 29.50 | 35.03 | 9.90 | 11.00 | 31.00 | 32.00 |

| M24 | 3.00 | 24.00 | 25.90 | 33.20 | 39.55 | 10.90 | 12.00 | 35.00 | 36.00 |

| M27 | 3.00 | 27.00 | 29.20 | 38.00 | 45.20 | 12.40 | 13.50 | 40.00 | 41.00 |

| M30 | 3.50 | 30.00 | 32.40 | 42.70 | 50.85 | 13.90 | 15.00 | 45.00 | 46.00 |

| M33 | 3.50 | 33.00 | 35.60 | 46.60 | 55.37 | 15.40 | 16.50 | 49.00 | 50.00 |

| M36 | 4.00 | 36.00 | 38.90 | 51.10 | 60.79 | 16.90 | 18.00 | 53.80 | 55.00 |

| M39 | 4.00 | 39.00 | 42.10 | 55.90 | 66.44 | 18.20 | 19.50 | 58.80 | 60.00 |

| M42 | 4.50 | 42.00 | 45.40 | 60.00 | 71.30 | 19.70 | 21.00 | 63.10 | 65.00 |

| M45 | 4.50 | 45.00 | 48.60 | 64.70 | 76.95 | 21.20 | 22.50 | 68.10 | 70.00 |

| M48 | 5.00 | 48.00 | 51.80 | 69.40 | 82.60 | 22.70 | 24.00 | 73.10 | 75.00 |

| M52 | 5.00 | 52.00 | 56.20 | 74.20 | 88.25 | 24.70 | 26.00 | 78.10 | 80.00 |

Lock Nut Applications:

- Automotive assembly and maintenance

- Machinery and equipment prone to vibration

- Aerospace applications requiring secure fastening

- Construction projects with high vibration

- Electronic devices and components

- Heavy machinery in industrial settings