Mail : sales@hariomsteel.com

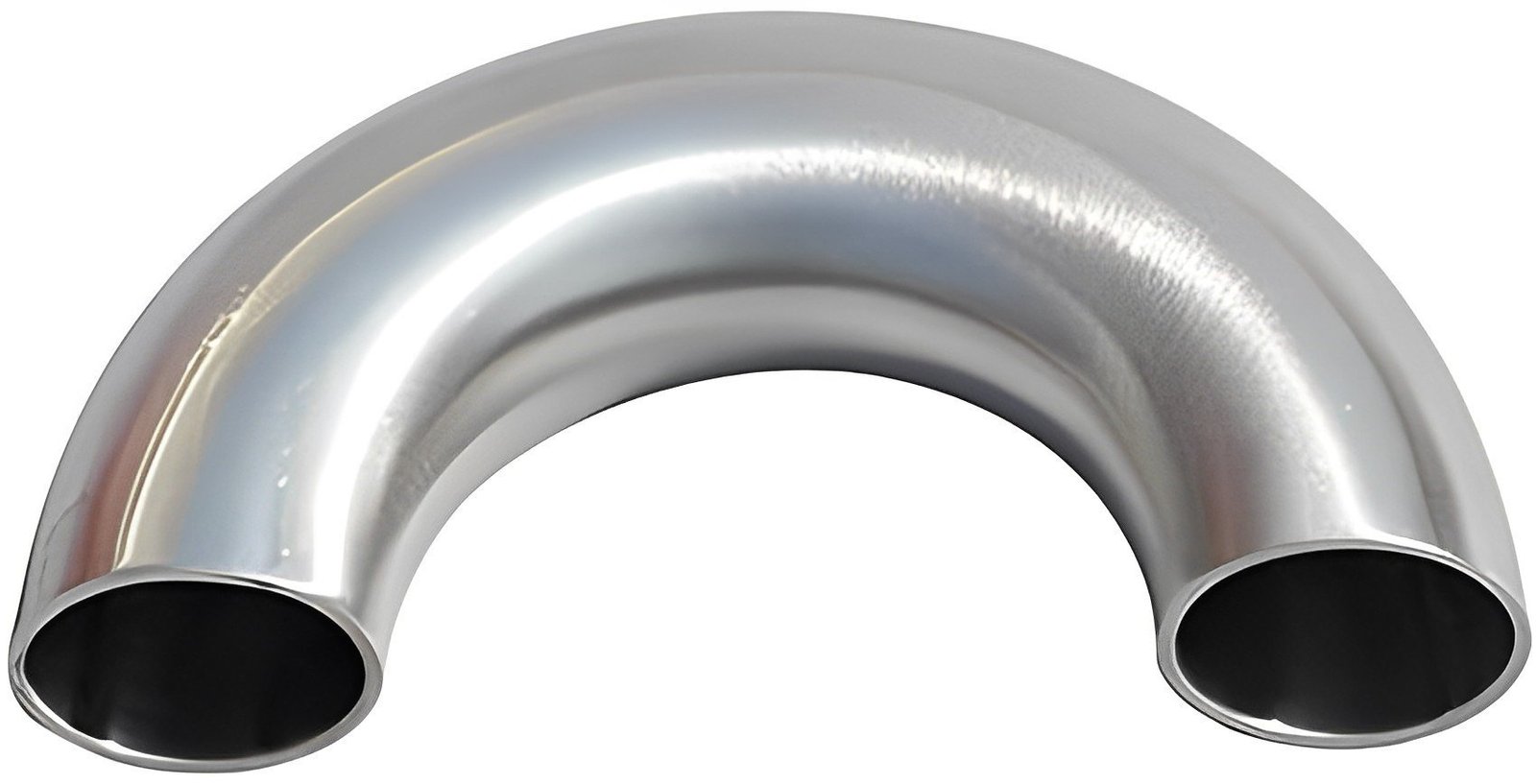

180-Degree Elbow

The 180-degree butt weld elbow is an essential fitting used in piping systems to create a complete U-turn, allowing fluid to flow back in the opposite direction. This fitting is commonly employed in various industries, such as oil and gas, petrochemical, power generation, and water treatment, where space constraints require a compact and efficient piping layout.

Constructed from high-quality materials, the 180-degree butt weld elbow is designed to withstand high pressures and extreme temperatures. Its butt weld design ensures a seamless and strong connection, reducing the likelihood of leaks and maintaining optimal flow characteristics. This fitting meets stringent international standards, including ASTM, ASME, and ANSI, ensuring reliability and long-term performance. Its robust design and precise manufacturing make it an ideal choice for demanding industrial applications where efficient flow management is critical.

Material Grades :

| Material Type | Grades |

|---|---|

| Carbon Steel | ASTM A 105/A694/ A350 LF3/A350 LF2 - F42, F46, F52, F56, F60, F65 |

| Stainless Steel | ASTM A 182 - F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316Ti, 316H, 316L, 321, 321H, 347, 347H, 904L |

| Duplex & Super Duplex | ASTM / ASME A/SA 182 - F44, F45, F51, F53, F55, F60, F61 |

| Nickel | 200, 201 |

| Monel | 400 |

| Inconel | 600, 601, 625, 800, 825 |

| Hastelloy | C-276 |

180-Degree Elbow Specifications:

| Specification | Details |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel (e.g., ASTM A234 WPB, ASTM A403 WP304, ASTM A420 WPL6) |

| Type | 180-Degree Butt Weld Elbow |

| Temperature Range | -29°C to 593°C (-20°F to 1100°F) |

| Corrosion Resistance | Exceptional resistance to corrosion, suitable for harsh environments |

| Standards | ASTM A234, ASME B16.9, MSS SP-75 |

| Sizes | 1/2" to 48" |

| Applications | Oil & Gas, Chemical Processing, Petrochemical, Power Plants, Pipelines |

| Production Technique | Butt Welding |

Dimension Chart :

| NPS | O.D. D | 180deg Long Rad | 180deg Short Rad | ||

| Center to Center O | Back to Face K | Center to Center O | Back to Face K | ||

| 1/2 | 21.3 | 76 | 48 | … | … |

| 3/4 | 26.7 | 76 | 51 | … | … |

| 1 | 33.4 | 76 | 56 | 51 | 41 |

| 1.1/4 | 42.2 | 95 | 70 | 64 | 52 |

| 1.1/2 | 48.3 | 114 | 83 | 76 | 62 |

| 2 | 60.3 | 152 | 106 | 102 | 81 |

| 2.1/2 | 73 | 190 | 132 | 127 | 100 |

| 3 | 88.9 | 229 | 159 | 152 | 121 |

| 3.1/2 | 101.6 | 267 | 184 | 178 | 140 |

| 4 | 114.3 | 305 | 210 | 203 | 159 |

| 5 | 141.3 | 381 | 262 | 254 | 197 |

| 6 | 168.3 | 457 | 313 | 305 | 237 |

| 8 | 219.1 | 610 | 414 | 406 | 313 |

| 10 | 273 | 762 | 518 | 508 | 391 |

| 12 | 323.8 | 914 | 619 | 610 | 467 |

| 14 | 355.6 | 1067 | 711 | 711 | 533 |

| 16 | 406.4 | 1219 | 813 | 813 | 610 |

| 18 | 457 | 1372 | 914 | 914 | 686 |

| 20 | 508 | 1524 | 1016 | 1016 | 762 |

| 22 | 559 | 1676 | 1118 | 1118 | 838 |

| 24 | 610 | 1829 | 1219 | 1219 | 914 |

Applications of 180-Degree Butt Weld Fittings:

180-degree butt weld fittings are designed to make a full turn in piping systems, effectively redirecting the flow by 180 degrees. They are commonly used in various applications, including:

- Oil and Gas Industry: Used to redirect the flow of oil, gas, and other fluids around obstacles or to change the direction in pipelines.

- Chemical Processing: Facilitates changes in flow direction in chemical reactors and pipelines, accommodating complex piping layouts.

- Water and Wastewater Systems: Allows for redirection of water flow in treatment plants and sewage systems, managing complex flow paths.

- Power Generation: Manages the flow of steam, water, and other fluids in power generation systems, especially where space constraints require direction changes.

- HVAC Systems: Redirects airflow in heating, ventilation, and air conditioning systems, particularly in compact or intricate ductwork layouts.

- Pulp and Paper Industry: Used to manage the flow of pulp, water, and chemicals in various stages of paper manufacturing processes.

- Automotive Industry: Applied in exhaust and cooling systems of vehicles where a complete redirection of flow is necessary.