Mail : sales@hariomsteel.com

Spring Washers

Spring washers, also known as lock washers, are designed to prevent fasteners from loosening due to vibrations and torque. Their unique shape allows them to exert a spring force, maintaining tension and holding the fastener in place.

- Helical or wave design that provides spring force

- Used to maintain tension and prevent loosening of fasteners

- Commonly used in applications with vibration or dynamic loads

- Available in various materials like steel, stainless steel, and brass

- Provides a locking mechanism without the need for adhesives or locking nuts

- Ideal for automotive, machinery, and electronic applications

Spring Washers Specification Table:

| Specification | Details |

|---|---|

| Type | Split lock washer, Belleville washer, Wave washer, etc. |

| Material | Stainless steel, Carbon steel, Phosphor bronze, etc. |

| Standard | DIN 127, ANSI B18.21.1, ISO 7089, etc. |

| Size Range | M2 to M100 |

| Hardness | 30 to 45 HRC (Rockwell Hardness Scale) |

| Surface Finish | Zinc plated, Black oxide, Plain, etc. |

| Application | Automotive, Aerospace, Machinery, Electronics, etc. |

| Temperature Range | -50°C to 300°C (-58°F to 572°F) |

| Corrosion Resistance | High, Medium, Low (depends on material and finish) |

Spring Washers Material Grade Table:

| Material | Grade | Description |

|---|---|---|

| Carbon Steel | ASTM A108 | General-purpose grade used in many applications |

| Stainless Steel | 304 | Corrosion-resistant, used in harsh environments |

| Stainless Steel | 316 | Higher corrosion resistance, especially against chlorides |

| Phosphor Bronze | C51000 | Excellent spring properties and good corrosion resistance |

| Inconel | 600 | Nickel-chromium alloy with high temperature resistance |

| Beryllium Copper | C17200 | High strength and conductivity, used in electrical applications |

| Alloy Steel | Grade 8 | High-strength steel for demanding applications |

| Brass | C36000 | Good machinability and corrosion resistance |

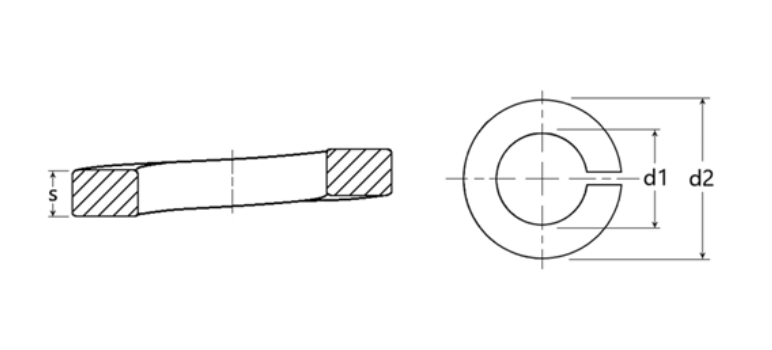

Spring Washers Dimensions Chart:

| Nominal Size | d1 | d2 | s | ||

|---|---|---|---|---|---|

| Inside Diameter | Outside Diameter | Thickness | |||

| M2 | 2.1 | 2.4 | 4.4 | 0.40 | 0.60 |

| M2.2 | 2.3 | 2.6 | 4.8 | 0.50 | 0.70 |

| M2.5 | 2.6 | 2.9 | 5.1 | 0.50 | 0.70 |

| M3 | 3.1 | 3.4 | 6.2 | 0.70 | 0.90 |

| M3.5 | 3.6 | 3.9 | 6.7 | 0.70 | 0.90 |

| M4 | 4.1 | 4.4 | 7.6 | 0.80 | 1.00 |

| M5 | 5.1 | 5.4 | 9.2 | 1.10 | 1.30 |

| M6 | 6.1 | 6.5 | 11.8 | 1.50 | 1.70 |

| M7 | 7.1 | 7.5 | 12.8 | 1.50 | 1.70 |

| M8 | 8.1 | 8.5 | 14.8 | 1.90 | 2.10 |

| M10 | 10.2 | 10.7 | 18.1 | 2.05 | 2.35 |

| M12 | 12.2 | 12.7 | 21.1 | 2.35 | 2.65 |

| M14 | 14.2 | 14.7 | 24.1 | 2.85 | 3.15 |

| M16 | 16.2 | 17.0 | 27.4 | 3.30 | 3.70 |

| M18 | 18.2 | 19.0 | 29.4 | 3.30 | 3.70 |

| M20 | 20.2 | 21.2 | 33.6 | 3.80 | 4.20 |

| M22 | 22.5 | 23.5 | 35.9 | 3.80 | 4.20 |

| M24 | 24.5 | 25.5 | 40.0 | 4.80 | 5.20 |

| M27 | 27.5 | 28.5 | 43.0 | 4.80 | 5.20 |

| M30 | 30.5 | 31.7 | 48.2 | 5.80 | 6.20 |

| M36 | 36.5 | 37.7 | 58.2 | 5.80 | 6.20 |

| M39 | 39.5 | 40.7 | 61.2 | 5.80 | 6.20 |

| M42 | 42.5 | 43.7 | 68.2 | 6.75 | 7.25 |

| M45 | 45.5 | 46.7 | 71.2 | 6.75 | 7.25 |

| M48 | 49.0 | 50.5 | 75.0 | 6.75 | 7.25 |

| M52 | 53.0 | 54.5 | 83.0 | 7.75 | 8.25 |

| M56 | 57.0 | 58.5 | 87.0 | 7.75 | 8.25 |

| M60 | 61.0 | 62.5 | 91.0 | 7.75 | 8.25 |

| M64 | 65.0 | 66.5 | 95.0 | 7.75 | 8.25 |

| M68 | 69.0 | 70.5 | 99.9 | 7.75 | 8.25 |

| M72 | 73.0 | 74.5 | 103.0 | 7.75 | 8.25 |

| M80 | 81.0 | 82.5 | 111.0 | 7.75 | 8.25 |

| M90 | 91.0 | 92.5 | 121.0 | 7.75 | 8.25 |

| M100 | 101.0 | 102.5 | 131.0 | 7.75 | 8.25 |

Spring Washer Applications:

Spring washers are essential in many mechanical and fastening applications. They are designed to provide a constant spring force that helps maintain the tension in the fastener assembly, preventing loosening and compensating for vibrations or thermal expansions. Their unique shape and properties make them valuable in applications where secure and reliable fastening is crucial.

- Maintaining tension and preventing loosening of fasteners

- Compensating for vibrations and dynamic loads

- Absorbing thermal expansion and contraction

- Providing a reliable connection in high-stress environments

- Enhancing the longevity and stability of assemblies

- Commonly used in automotive, aerospace, and machinery applications