Mail : sales@hariomsteel.com

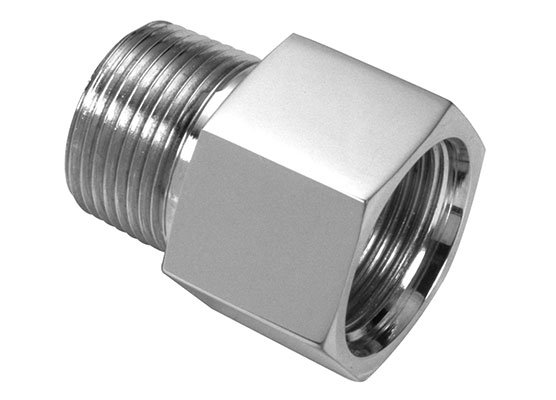

Adapters

Forged fittings adapters are essential components in piping systems, designed to connect pipes of different sizes or types, ensuring a seamless and secure transition. Known for their versatility and adaptability, these adapters are widely used in various industrial applications, including oil and gas, chemical processing, and construction.

Manufactured from high-quality forged steel, forged fittings adapters offer exceptional strength and durability, providing reliable performance even under high pressures and extreme temperatures. These adapters comply with stringent international standards, such as ASTM, ASME, and DIN, ensuring superior quality and longevity.

Material Grades :

| Material Type | Grades |

|---|---|

| Carbon Steel | :ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65,ASTM A350, LF2, LF3 |

| Stainless Steel | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L |

| Duplex & Super Duplex | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Nickel | 200, 201 |

| Monel | 400, 500 |

| Inconel | 600, 601, 625, 800, 825 |

| Hastelloy | C-276 |

Adapters Specifications:

| Specification | Details |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Brass, PVC, Aluminum |

| Type | Adapters |

| Temperature Range | -40°C to 200°C (-40°F to 392°F) (varies with material) |

| Pressure Rating | Up to 6000 psi (varies with material and design) |

| Standards | ASME, API, ANSI, ASTM |

| Sizes | 1/2" to 24" (varies with material and design) |

| Applications | Oil & Gas, Waterworks, Chemical Processing, HVAC Systems, Construction |

| Production Technique | Machined, Cast, Forged (varies with material and design) |

Dimension Chart :

| DN | Nom. Pipe Size A | D | L | Threaded Size B |

| 8 | 1/4" | 19 | 33 | 1/8" |

| 10 | 3/8" | 22 | 35 | 1/4" |

| 15 | 1/2" | 28 | 42 | 3/8" |

| 20 | 3/4" | 35 | 47 | 1/2" |

| 25 | 1" | 44 | 55 | 3/4" |

| 32 | 1-1/4" | 57 | 63 | 1" |

| 40 | 1-1/2" | 64 | 66 | 1-1/4" |

| 50 | 2" | 76 | 76 | 1-1/2" |

| 65 | 2-1/2" | 92 | 90 | 2" |

| 80 | 3" | 108 | 110 | 2-1/2" |

| 100 | 4" | 140 | 120 | 3" |

Applications of Forged Fittings Adapters:

Forged fittings adapters are crucial in various applications due to their ability to connect pipes of different sizes or types, ensuring a secure and efficient transition. Key areas of application include:

- Oil and Gas Industry: Used to connect different sizes of pipelines and equipment, ensuring a secure and leak-proof connection in high-pressure environments.

- Chemical Processing: In pipelines, reactors, and storage tanks to handle corrosive chemicals and maintain the integrity of the system.

- Water Treatment: Employed in filtration and distribution systems to connect various components, ensuring a reliable and leak-free operation.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems to connect pipes of different sizes, ensuring efficient and flexible system configurations.

- Food and Beverage Industry: In processing and packaging equipment where hygiene and safety are critical, providing secure connections for various pipe sizes.

- Pharmaceutical Industry: Utilized in sterile processing systems to connect equipment and piping, ensuring contaminant-free and leak-proof connections.

- Fire Protection Systems: Installed in sprinkler and fire suppression systems to connect different pipe sizes, ensuring reliable and efficient performance in emergency situations.