Mail : sales@hariomsteel.com

Union

The forged union is an essential fitting in piping systems, designed to connect two pipes or tubes while allowing for easy disassembly and reassembly. Known for its versatility and convenience, this component is widely used in various industrial applications, including oil and gas, chemical processing, and HVAC systems.

Crafted from high-quality forged steel, the union provides exceptional strength and durability, ensuring a secure and leak-proof connection. It complies with stringent international standards, such as ASTM, ASME, and DIN, to deliver reliable performance and longevity even in demanding conditions.

Material Grades :

| Material Type | Grades |

|---|---|

| Carbon Steel | ASTM A 105/A694/ A350 LF3/A350 LF2 - F42, F46, F52, F56, F60, F65, F70 |

| Stainless Steel | ASTM / ASME A/SA 182 - F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L |

| Duplex & Super Duplex | ASTM / ASME A/SA 182 - F44, F45, F51, F53, F55, F60, F61 |

| Nickel | 200, 201 |

| Monel | 400 |

| Inconel | 600, 601, 625, 800, 825 |

| Hastelloy | C-276 |

Union Specifications:

| Specification | Details |

|---|---|

| Material | Forged Steel (e.g., ASTM A105, A350 LF2, A694 F65) |

| Type | Union |

| Temperature Range | -50°C to 450°C (-58°F to 842°F) (varies with material) |

| Pressure Rating | Up to 6000 psi (varies with material and design) |

| Standards | ASME B16.11, API 5CT |

| Sizes | 1/2" to 4" (varies with material and design) |

| Applications | Oil & Gas, Petrochemical, Chemical Processing, Waterworks, HVAC Systems |

| Production Technique | Forged and Machined from Solid Steel |

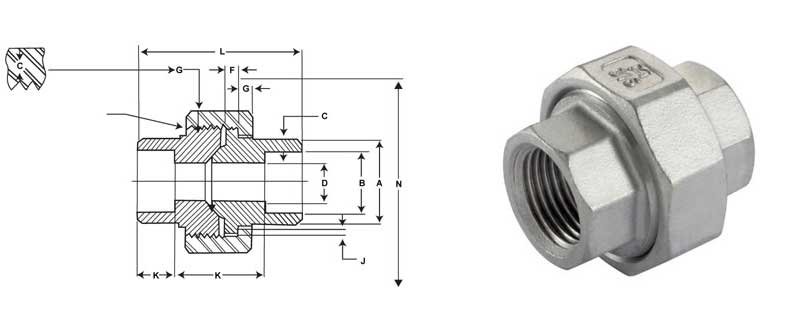

Dimension Chart :

| Nom. Pipe Size | Pipe End Min | Socket Bore Dia. | Socket Wall Min. | Water Way Bore | Laying Length | Male Flange Min. | Nut Min. | Threads Per 25.4 Max | Bearing Min. | Depth of Socket Min. | Length Assem. Nominal | Clear Assem. Nut |

| A | B | C | D | E | F | G | H | J | K | L | N | |

| 1/8 | 21.8 | 10.92 10.67 | 3.17 | 6.83 6.43 | 22.4 19.0 | 3.17 | 3.17 | 16 | 1.24 | 9.6 | 41.1 | 49.0 |

| ¼ | 21.8 | 14.22 13.97 | 3.30 | 9.85 9.45 | 22.4 19.0 | 3.17 | 3.17 | 19 | 1.24 | 9.6 | 41.4 | 49.0 |

| 3/8 | 25.9 | 17.78 17.53 | 3.48 | 13.92 13.51 | 26.9 20.6 | 3.43 | 3.43 | 14 | 1.37 | 9.6 | 46.0 | 55.0 |

| ½ | 31.2 | 21.84 21.59 | 4.06 | 17.47 17.07 | 26.9 20.6 | 3.68 | 3.68 | 14 | 1.50 | 9.6 | 49.0 | 57.0 |

| ¾ | 37.1 | 27.18 26.92 | 4.27 | 21.79 21.39 | 31.8 25.4 | 4.06 | 4.06 | 11 | 1.68 | 12.7 | 56.9 | 67.0 |

| 1 | 45.5 | 34.04 33.78 | 4.95 | 28.14 27.74 | 34.3 26.2 | 4.57 | 4.44 | 11 | 1.85 | 12.7 | 62.0 | 79.0 |

| 11/4 | 54.9 | 42.67 42.42 | 5.28 | 35.76 35.36 | 40.6 32.5 | 5.33 | 5.21 | 11 | 2.13 | 12.7 | 71.1 | 94.0 |

| 11/2 | 61.5 | 48.77 48.51 | 5.54 | 41.61 41.20 | 42.2 34.0 | 5.84 | 5.59 | 10 | 2.31 | 12.7 | 75.5 | 111.0 |

| 2 | 75.2 | 61.47 61.21 | 6.05 | 52.53 52.12 | 45.3 37.3 | 6.60 | 6.35 | 10 | 2.69 | 15.8 | 86.1 | 132.0 |

| 21/2 | 91.7 | 74.17 73.66 | 7.65 | 64.72 64.31 | 61.7 52.1 | 7.49 | 7.11 | 8 | 3.07 | 15.8 | 102.4 | 148.0 |

| 3 | 109.2 | 90.17 89.66 | 8.31 | 77.67 77.27 | 63.8 53.6 | 8.25 | 8.00 | 8 | 3.53 | 15.8 | 109.0 | 175.0 |

Applications of Union Forged Fittings:

Union forged fittings are highly versatile components used to connect two pipes or tubes, providing an efficient solution for easy assembly and disassembly in various industrial applications. Key areas of application include:

- Oil and Gas Industry: Used in pipelines and equipment for easy maintenance and repairs, ensuring a secure and leak-proof connection under high pressures and harsh conditions.

- Chemical Processing: Essential for connecting pipes and equipment that handle corrosive chemicals, allowing for quick and safe disassembly for cleaning and inspection.

- Water Treatment: Employed in filtration systems and pipelines to enable convenient disassembly for maintenance and replacement of components.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems for connecting various pipes and ensuring easy access for maintenance and repairs.

- Food and Beverage Industry: In processing and packaging equipment where sanitary conditions are crucial, allowing for easy cleaning and reassembly.

- Pharmaceutical Industry: Utilized in systems where sterile connections are required, providing a reliable and easy-to-maintain solution for critical processes.

- Fire Protection Systems: Installed in sprinkler systems and fire suppression equipment for quick installation and maintenance, ensuring reliable operation in emergency situations.