Mail : sales@hariomsteel.com

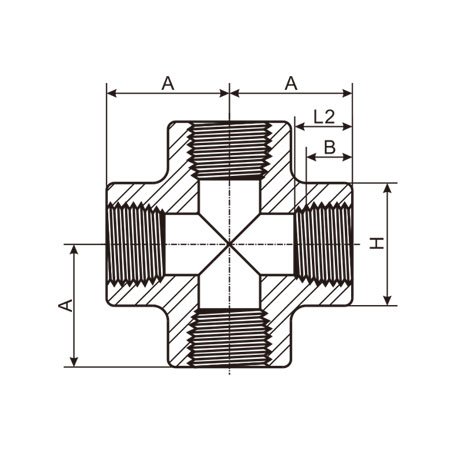

Cross

The forged steel cross is an essential fitting in piping systems, designed to connect four pipes at a central junction. This robust component is engineered to handle high-pressure and high-temperature conditions, making it ideal for use in demanding industrial environments such as oil and gas, chemical processing, and power generation.

Constructed from high-grade forged steel, the cross offers exceptional strength and durability. Its precise manufacturing process ensures a seamless connection and reliable performance under stress. Adhering to stringent industry standards such as ASTM, ASME, and DIN, the forged steel cross provides long-lasting reliability and safety for critical piping applications.

Material Grades :

| Material Type | Grades |

|---|---|

| Carbon Steel | ASTM SA105, ASTM SA106, ASTM A350 LF2, LF3 |

| Stainless Steel | ASTM / ASME 201, 202, 301, 304, 304L, 310, 310S, 316L, 316TI, 317, 317L, 321, 347, 409, 409M, 409L, 410, 410S, 420, 430, 431, 441, 444, 446, 17.4PH, 904L |

| Duplex & Super Duplex | ASTM / ASME SA 790 |

| Nickel | 200, 201 |

| Monel | 400, 500 |

| Inconel | 600, 601, 625, 800, 825 |

| Hastelloy | C-276 |

Cross Specifications:

| Specification | Details |

|---|---|

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Brass, Monel |

| Type | Forged Cross |

| Temperature Range | -50°C to 400°C (-58°F to 752°F) |

| Pressure Rating | Up to 6000 psi (varies with material and design) |

| Standards | ASME, API, ASTM |

| Sizes | 1/2" to 24" (varies with material and design) |

| Applications | Oil & Gas, Petrochemical, Waterworks, Construction, and Industrial Applications |

| Production Technique | Forged from Solid Metal, Heat Treated |

Dimension Chart :

| DN | Nom. Pipe Size | Center to End Elbow,Tee,Cross A | Center to End 45°Elbow C | Outside Diameter Of Band H | Minimum Wall Thickness G | Length Of Thread Min.(1) | |||||||||

| 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | B | L2 | ||

| 6 | 1/8" | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 8 | 1/4" | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 10 | 3/8" | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 15 | 1/2" | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 20 | 3/4" | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 25 | 1" | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 32 | 1-1/4" | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 40 | 1-1/2" | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 50 | 2" | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 65 | 2-1/2" | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 80 | 3" | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 100 | 4" | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |

Applications of Forged Steel Crosses:

Forged steel crosses are crucial in various applications due to their ability to connect four pipelines at a single junction, providing flexibility and reliability in complex piping systems. Key areas of application include:

- Oil and Gas Industry: Used in refining, distribution, and production facilities to handle high-pressure and high-temperature fluids.

- Chemical Processing: In pipelines and processing units to efficiently manage the flow of various chemicals under rigorous conditions.

- Power Generation: In steam and water systems of power plants where durable and high-strength fittings are necessary.

- Petrochemical Industry: For the safe transportation and handling of hydrocarbons and other chemicals.

- Water Treatment: In water distribution systems and treatment plants to ensure robust connections and prevent leaks.

- HVAC Systems: In heating, ventilation, and air conditioning systems to manage fluid flow in complex configurations.